What are CLOSED-CORNER frames?

While most frames today are joined from mass-produced, pre-finished molding, closed-corner (also called finished-corner) frames are finished after joining. Before framing became a big business frames were joined in the raw—using time-honored joining methods—and then finished, as a piece of furniture would be. The traditional method, which we use exclusively, makes for stronger, cleaner and more even corners—and more enduring and beautiful frames.

While most frames today are joined from mass-produced, pre-finished molding, closed-corner (also called finished-corner) frames are finished after joining. Before framing became a big business frames were joined in the raw—using time-honored joining methods—and then finished, as a piece of furniture would be. The traditional method, which we use exclusively, makes for stronger, cleaner and more even corners—and more enduring and beautiful frames.

What’s wrong with how most frames are made?

The vast majority of frames available today are made from mass-produced molding, finished in length and then chopped down and put together with metal or plastic fasteners or nails to make individual frames. The corners of such frames are neither as strong nor as clean and even as they should be. Frames made this way don’t allow for the sound joinery we expect of quality wooden furnishings. And at best, the finish, by necessity, is broken where the sides meet.

The vast majority of frames available today are made from mass-produced molding, finished in length and then chopped down and put together with metal or plastic fasteners or nails to make individual frames. The corners of such frames are neither as strong nor as clean and even as they should be. Frames made this way don’t allow for the sound joinery we expect of quality wooden furnishings. And at best, the finish, by necessity, is broken where the sides meet.

The conventional joining methods of the framing industry have the advantage of being low-cost because they are quick and require little skill and training. But, being mechanically inferior, they don’t hold up to either time or close scrutiny. Even when they’re not abused, the corners of conventional frames usually break down before too many years, simply because the joinery techniques aren’t designed to withstand normal glue failure and wood movement, as proper wood joints are. Watch video…

The CRAFT of closed-corner Frames

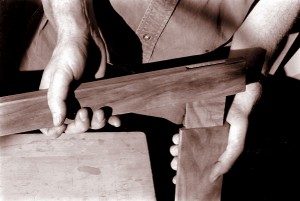

The corners of a frame, the joints, are its main points of strength and integrity, and are a primary concern for the serious frame-maker. Finishing frames after they’re joined allows for much stronger, more durable joinery (using splines , mortise-and-tenon joints and lap joints). Making our frames this way also means the joints are more even, since they can be sanded, planed and carved to meet perfectly. And the joints are cleaner, since the stain and varnish are continuous over the joint.

, mortise-and-tenon joints and lap joints). Making our frames this way also means the joints are more even, since they can be sanded, planed and carved to meet perfectly. And the joints are cleaner, since the stain and varnish are continuous over the joint.

Of course it also means we aren’t limited to a molding factory’s limited color offerings, but can finish the frame to exactly the right color and shade for your picture.

A great many gilded frame  manufacturers produce closed corner frames, leafing the frames after joining. Holton Studio, however, works in the old “Cabinet-maker’s Frame” tradition—a legacy of ungilt (or minimally gilt) hardwood frames by furniture- and cabinet-makers that represents the origin of picture frames in Europe. Cabinet-makers’ frames are put together with the traditional expert methods of the professional joiner. Rather than relying on the dubious strength of nails and screws, traditional cabinet-makers’ frames were more likely than gilt frames to be joined with mortise & tenon, lap-joints and splines.

manufacturers produce closed corner frames, leafing the frames after joining. Holton Studio, however, works in the old “Cabinet-maker’s Frame” tradition—a legacy of ungilt (or minimally gilt) hardwood frames by furniture- and cabinet-makers that represents the origin of picture frames in Europe. Cabinet-makers’ frames are put together with the traditional expert methods of the professional joiner. Rather than relying on the dubious strength of nails and screws, traditional cabinet-makers’ frames were more likely than gilt frames to be joined with mortise & tenon, lap-joints and splines.

The ART of closed-corner frames

Beyond allowing for stronger joinery and more integrity to the finish, closed-corner frames make possible the full artistry of frame-making, opening up infinite design possibilities which are natural and integral to the materials and construction of the frame and not simply applied.

Beyond allowing for stronger joinery and more integrity to the finish, closed-corner frames make possible the full artistry of frame-making, opening up infinite design possibilities which are natural and integral to the materials and construction of the frame and not simply applied.  One of the great contributions of the Arts and Crafts Movement was its understanding of construction as a basis of design and as part of the expressive affect of a piece. As structural points of strength, a frame’s corners are artistic points of strength as well. The frame-maker takes advantage of this to articulate the frame’s form with any number of decorative treatments to the corner design and detailing. At right, corner samples of some small mitered frame designs show a variety of artistic possibilities for enhancing the corners—an option afforded by closed-corner frames.

One of the great contributions of the Arts and Crafts Movement was its understanding of construction as a basis of design and as part of the expressive affect of a piece. As structural points of strength, a frame’s corners are artistic points of strength as well. The frame-maker takes advantage of this to articulate the frame’s form with any number of decorative treatments to the corner design and detailing. At right, corner samples of some small mitered frame designs show a variety of artistic possibilities for enhancing the corners—an option afforded by closed-corner frames.

Cap molding with carved foliage, being made for large historical painting. More about this frame…

Look no further than the entry for the word “art” in Webster’s Dictionary to understand this elemental relationship between construction and beauty: the base of the word art is “ar-, to join, fit together,” and is “akin to Greek harmos, joint,” the root of the word harmony.

The point formed by the corner is, in a sense, the point of the frame, the art of frame-making and, in fact, of making pictures: to express—literally, to “press out” the artist’s vision into the world to join it to the life and larger creation of which it’s a part. The four corners of the frame radiate the picture in the fashion of a star, or any number of natural forms, including flower petals or leaf clusters enlivened above all by their primal aspiration toward the source of life in sun, oxygen, and water. For this reason, we can suppose, the most suitable decorative motifs for corners have been flowers and leaves, or patterns derived from them.

The significance of the corners is therefore, if rarely understood or explained, keenly felt: when the frame-maker looks for “something to do with the frame”—a way to decorate it to give a suitably significant and enhancing place to the picture—instinct can’t help but go to the corners.

See the gallery at the bottom of page for frames in carved corner designs.

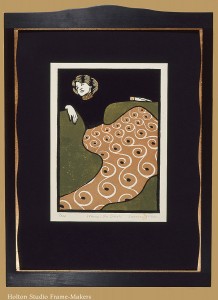

Laura Wilder blockprint, “Woman on Couch.” More about this piece…

Closed-corner construction also allows the frame to be designed with a more interesting overall form emphasizing other points of strength, such as the centers and the top. At right, the overall form of this mortise-and-tenon “Secession” frame was designed in sympathy with the forms in the print. In this case the center of the top member of the frame is articulated—a design element that would not be easy or natural in making the frame with pre-finished molding. Also the treatment of the copper-leafed liner is possible.

The sense of quality and integrity, honestly earned, in closed-corner hardwood frames contributes greatly to the presence and artistic effectiveness of the frame.

Examples of mitered frames with special corners—

See more examples in the frame catalog section, Mitered Frames—Special Corners…

- No. 16 CV Points on a needlepoint

- William Rice print in No. 14 CV Scallops

- No. 16.2 “Gimson” on print by Dard Hunter (1883-1966) (Roycroft Inn). Linoleum block print.

- William Rice print in No. 14 CV with stops

- Richmond Kelsey print in No. 16 CV “S” Corners

- Sharon Calahan painting in carved corner compound frame

- Kevin Courter painting in carved corner compound frame

- Paul Kratter painting in carved corner compound frame

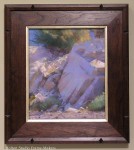

- Carved corner compound frame on pastel*

- Gustave Baumann print in carved corner compound frame

- Carved compound frame on historical painting*

- Hyatt Moore painting, “Cheyenne Boy,” in carved corner frame